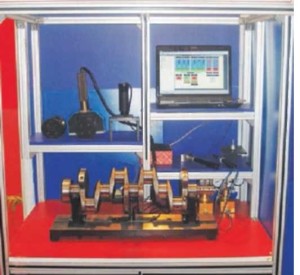

Keeping an Eye on Future & Responding to the needs of Industry for greater Precision, greater speed & labour saving solution with precision measuring technology, MGPL has successfully entered Air gauging, Air Electronic gauging, Auto gauging & Multigauging.

MGPL Executed Many projects for multiparameter checking of variety of components, MGPL developed one of the most advanced interface unit which can be used with specially designed relay output for marking or can use for sorting.

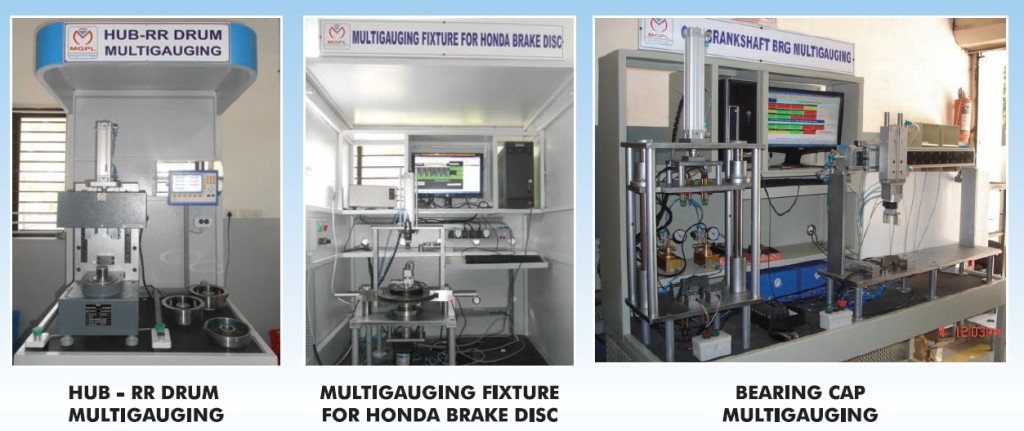

MGPL has successfully completed many multigauging projects for various components below which are running trouble free to our customer premises. Some of them are as below.

- CRANKSHAFT 2 & 4 WHLR

- VARIOUS SHAFT

- DIFFERENTIAL CASE

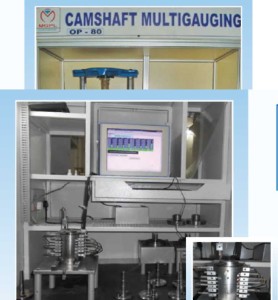

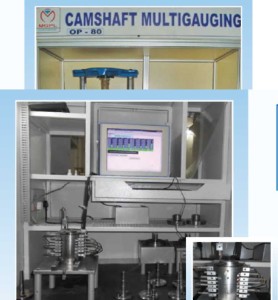

- CAMSHAFT

- CON ROD

- ENGINE VALVE

- CYLINDER BLOCK

- CRANK PIN

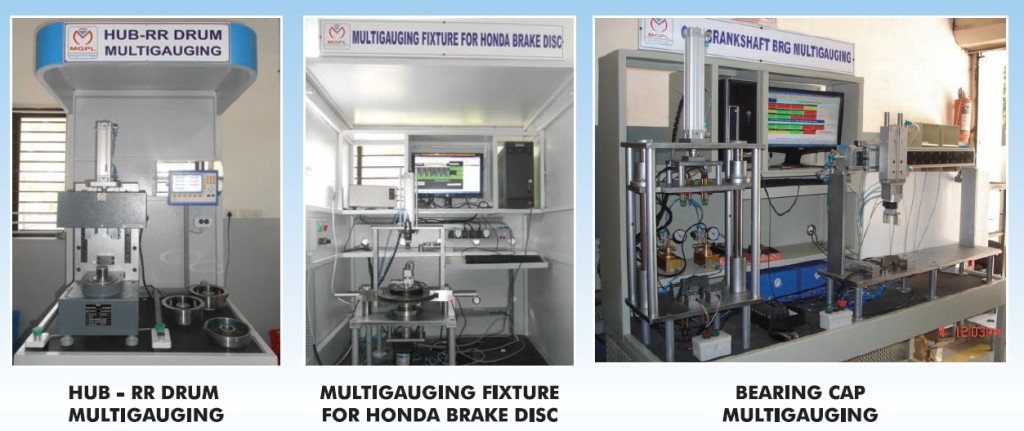

- BRAKE DISC/DRUM

- TURBINE HOUSING

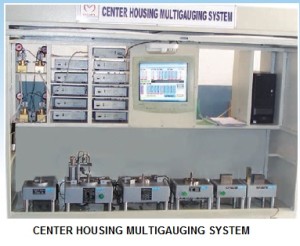

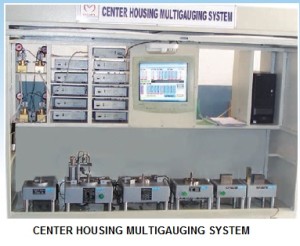

- CENTER HOUSING

- HOUSING COMPRESSOR

- RING NOZZLE

- BACK/SEAL PLATE

- BUSH/BEARINGS

- BEARING CAP

- HUB

- PISTON

- CONTROL VALVE MANIFOLD

- METAL INJECTION MOLDING COMPONENTS : FASTER FACE, SPACER, VANE ETC.

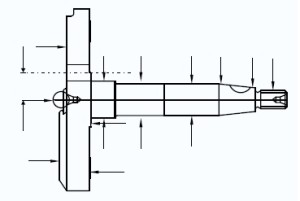

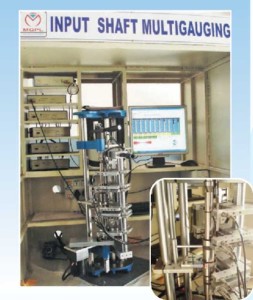

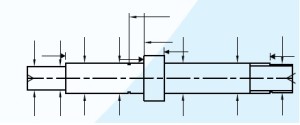

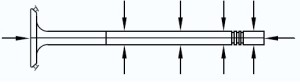

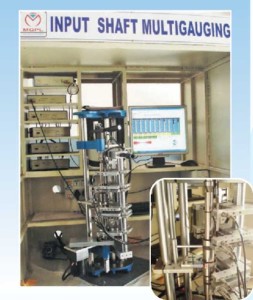

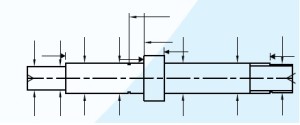

SHAFT MULTIGAUGING

SHAFT MULTIGAUGING

(Horizontal Model)

Proven design suitable for all kinds of shafts.

Flexible fixture to checkdiameters & runouts.

Offered in Horizontal as well as Vertical design.

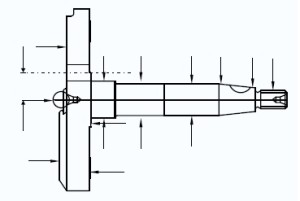

SHAFT MULTIGAUGING (Vertical Model)

MGPL Designed In Between Center gauging fixture is useful to use with large Variety of shafts.

e.g. Cam Shafts, Transmission Shafts, Input, Output Shafts etc. parameter to check:

- Diametar

- Lengths

- Concentricity.

- Runouts

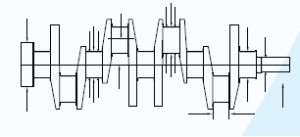

CRANKSHAFT MULTI GAUGING (2 Wheelers)

TO CHECK:

- Outside Diameters (2/3 places).

- un Out.

- Inside Dia.

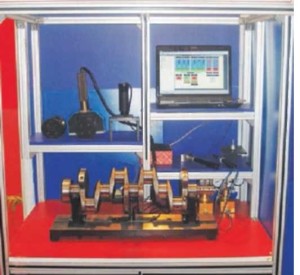

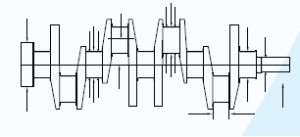

CRANKSHAFT MULTIGAUGING (4 WHEELERS)

MGPL supplies total solution measuring following parameters of crankshafts.

- Pin diameter &Ovality (Convexity if required).

- Journal Diameterand Ovality (Convexity if required).

- Flange End & Gear End Diameter.

- THROW(Center Distance).

- Flange end, Gear End,

Run outsw.r.t. 2 Journals PIN Width Woodruff Width

CONNECTING ROD MEASUREMENT

To check:

- Small End Diameter.

- Big End Diameter.

- Twist.

- Bend.

- Center Distance.

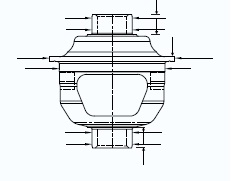

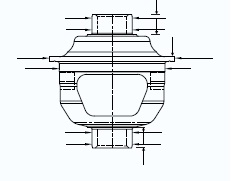

DIFFERENTIAL CASE MEASUREMENT

- Outside Diameter.

- Inside Diameter.

- Run out.

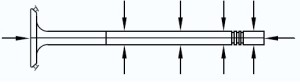

ENGINE VALVE MULTIGAUGING

Stem Dia Measurement at 3 Places.

- Stem Diameter.

- Groove Diameter.

- Total Length.

- Gauge Plane Length.

CRANKPIN MULTIGAUGING

Stem Dia Measurement at 3 Places.

- Checking Diameters.

- Grading.

- Grade marking.

CYLINDER BLOCK MEASUREMENT

CYLINDER BLOCK MEASUREMENT

- Inside bore measurement at 2-3 heights.

- Grading.

- Grade marking.

PISTON MEASUREMENT

- Diameter Skirt.

- Diameter Groove.

- Diameter Ovality.

- Pin Bore Dia.

- Pin bore center Height.

HUB MEASUREMENT

- Inner Diamters

- Circularity of ID's

- Squareness of ID w.r.t Face

- Cylindricity

- Diameter Ovality.

Gauging for Metal injection molding components.

FASTER FACE GAUGING

FASTER FACE GAUGING

To Check

SPACER GAUGING

SPACER GAUGING

To Check

Control Valve Manifold Multigauging

To Check

- This gauging is designed to check 26 bores at a time.

- Operator needs to load component manually & press the start button.

- This is air gauge principle.All APG's mounted on slides will automatically moved to component for checking.

COVER & HOUSING Multigauging.

- Inner / Outer Diameters

- Heights

- Depth

- Squareness

VARIOUS COMPONENTS

CRANKCASE / BREAK DRUM / BREAK DISC CENTER HOUSING

HOUSING TURBINE BEARING CAP /BACKPLATE MEASUREMENT

- Inside Diameters.

- Outside Diameters.

- Thickness Variation,